What is Machine Vision?

Definition and Key Concepts

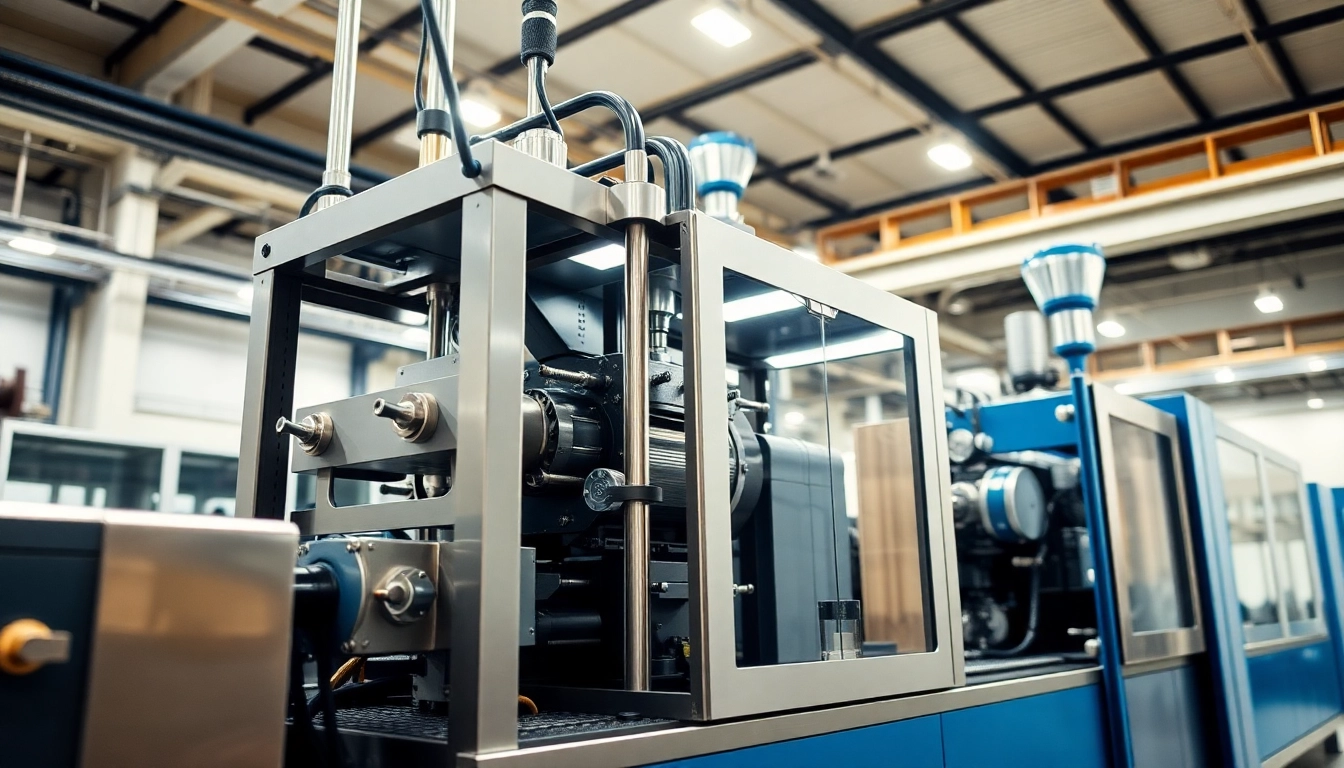

Machine vision refers to the technology and methodologies that empower machines to interpret visual information from the world around them. It utilizes digital images captured through cameras combined with sophisticated algorithms to analyze the images for specific tasks. Applications range from quality control in manufacturing to enabling robotic systems to identify and interact with their environment. At its core, machine vision leverages machine vision systems to automate processes that traditionally required human oversight, enhancing efficiency and precision in various applications.

How Machine Vision Works

The operation of machine vision systems involves several critical steps:

- Image Acquisition: Cameras capture images as raw data. This can occur in real-time or through recorded footage.

- Image Processing: The captured images are processed using algorithms to enhance features, remove noise, and prepare data for analysis.

- Feature Extraction: Relevant features are identified and selected from the processed image, such as edges, contours, and textures.

- Decision Making: Based on predetermined criteria, the system makes decisions regarding the objects in the image (e.g., pass/fail assessments).

- Output: The results of the analysis are relayed to the user or a connected system to facilitate further actions, such as sorting or logging performance metrics.

Common Applications

Machine vision is essential in various sectors, primarily due to its ability to automate and enhance accuracy in processes. Some common applications include:

- Quality Inspection: Automated inspections are employed in manufacturing to identify defects in products, ensuring they meet quality standards.

- Guidance: Robotics systems utilize machine vision for guidance in assembly lines, ensuring precise placement and alignment of components.

- Barcode and Optical Character Recognition: Machine vision systems are extensively used to read barcodes and characters, facilitating inventory tracking and data input.

- Medical Imaging: In healthcare, machine vision assists in analyzing scans and images for diagnostics.

Machine Vision vs. Computer Vision

Defining the Differences

While the terms “machine vision” and “computer vision” are sometimes used interchangeably, they refer to distinct concepts. Machine vision is primarily focused on automation in industrial settings, leveraging cameras and processing systems to perform specific functions. In contrast, computer vision encompasses a broader range of visual input processing, often involving more complex interpretation tasks that mimic human visual perception, such as facial recognition and scene understanding.

Use Cases for Each Technology

Machine vision finds use predominantly in industrial environments where speed, precision, and repeatability are paramount. It excels in:

- Automated quality inspection

- Robotic assembly line guidance

- Parts and product sorting

Computer vision, however, finds applications in:

- Self-driving cars identifying traffic signs and pedestrians

- Healthcare imaging systems that analyze X-rays and MRIs

- Smart cameras for security that recognize faces and license plates

Integration in Modern Technology

The synergy between machine vision and other technologies, such as artificial intelligence (AI) and the Internet of Things (IoT), is shaping future innovations. For instance, the integration of AI into machine vision systems enhances their capability to learn and adapt over time, leading to improvements in accuracy and efficiency. This convergence extends beyond traditional manufacturing into fields like autonomous vehicles, where machine vision systems play a vital role in real-time decision-making processes.

Components of a Machine Vision System

Cameras and Imaging Technologies

The cameras chosen for a machine vision system significantly influence its performance. Various types exist, including:

- CCD Cameras: Known for their high image quality and low noise output, suitable for applications requiring clear images.

- Cmos Cameras: Faster and energy-efficient, suitable for high-speed applications.

- Infrared Cameras: Used for thermal imaging and detecting temperature variations in various environments.

Processing Hardware and Software

The backbone of a machine vision system lies in its processing capabilities. Dedicated vision processors are designed specifically for image processing tasks, while software packages encompass algorithms necessary for tasks, such as:

- Image filtering

- Pattern recognition

- Machine learning integration for adaptive learning

Lighting Techniques

A critical element of machine vision, lighting directly impacts image quality. The choice of lighting depends on the application — options range from:

- Backlighting: Often used to highlight edges in transparent materials.

- Diffuse Lighting: Reduces shadows, providing even illumination across the surface.

- Structured Light Systems: Projects a known pattern onto the object to assist in 3D surface reconstruction.

Impact of Machine Vision on Industries

Quality Control and Inspection

Machine vision revolutionizes quality control processes, allowing for consistent, rapid inspections free of human error. This ensures that products assembled or manufactured are up to specified standards. For instance, in the automotive industry, machine vision systems assess components at high speed, drastically reducing defects and recalls.

Automation and Efficiency Improvements

The automation capabilities of machine vision lead to significant efficiency enhancements in production lines. By replacing manual inspection, companies experience reduced labor costs while increasing throughput. The reduction in processing time can be illustrated through case studies, such as a leading electronics manufacturer that reported a 50% decrease in inspection times by switching to automated machine vision systems.

Case Studies and Success Stories

Numerous businesses have successfully integrated machine vision into their operations. A notable case is a food processing plant that adopted machine vision for packaging inspection. The system significantly reduced the incidence of mislabeled products, which historically resulted in costly recalls. The accuracy increased to 98%, showcasing the potential of machine vision systems in safeguarding brand integrity.

Future Trends in Machine Vision Technology

AI and Deep Learning Integration

The trajectory of machine vision is increasingly intertwined with advancements in AI and deep learning. These technologies empower machine vision systems to handle more complex tasks, such as recognizing not just defects but also classifying products based on embeddings learned from large datasets. As these capabilities grow, businesses will find more nuanced applications, pushing the boundaries of what machine vision can achieve.

Emerging Technologies and Innovations

The future also holds potential with emerging technologies such as 5G, which promises faster data transfer, enabling real-time processing in remote environments. Enhanced sensors with higher resolutions and better processing power will further augment machine vision’s functionality, making it a pivotal player in the context of Industry 4.0.

Challenges and Opportunities in Adoption

Despite the advancements, companies face challenges in adopting machine vision technology, including high initial costs, integration into existing infrastructures, and a shortage of skilled personnel. However, these hurdles also present opportunities for training and development. Harnessing partnerships with technology providers can facilitate smoother transitions, empowering organizations to upgrade their processes and remain competitive.